GearOil by SEW-EURODRIVE Base 150

97% supplied in 5 working days

Bank transfer or Credit Card (master card & visa) payment

Quality brands only

genuine packages

Save costs

take control of your costs

save time and money

UK Deliveries

incoterm DAP

QUESTIONS?

GearOil by SEW-EURODRIVE Base 150

Benefits of GearOil by SEW-EURODRIVE Base 150 premium lubricants

With over 90 years of experience in developing and constructing gear units and implementing them in countless customer applications, SEW has extensive tribological knowledge at its disposal. SEW's gear unit oils of the GearOil by SEW-EURODRIVE series were developed based on this expertise and on the insights gained from comprehensive test runs. OilOnline is a valued supplier of SEW-EURODRIVE for the Global service aftermarket.

GearOil by SEW-EURODRIVE Base 150 offers optimum protection for your valuable gear unit. It ensures that all components are perfectly matched to each other.

Furthermore, using GearOil by SEW-EURODRIVE Base 150 has a number of benefits that will help you cut costs. GearOil by SEW-EURODRIVE Base 150 is available as a mineral-based CLP gear unit oil.

Application GearOil by SEW-EURODRIVE Base 150

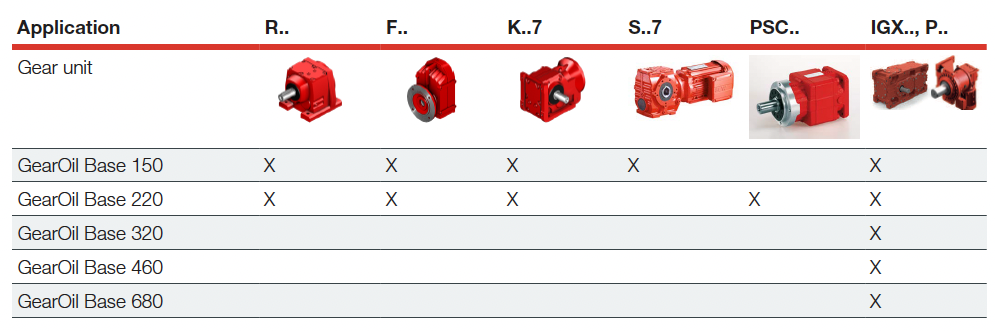

Mineral-based GearOil by SEW-EURODRIVE Base 150 was developed specifically for use in helical (R..), parallel-shaft helical (F..), helical-worm (S..) and helical-bevel (K..) gear units, in PS.C.. series planetary servo gear units, and in X.. and P.. series industrial gear units. GearOil by SEW-EURODRIVE Base 150 is the ideal lubricant for normal ambient conditions in industrial environments. The following GearOil by SEW-EURODRIVE Base 150 lubricants are available for use in SEW‑EURODRIVE gear units:

GearOil by SEW-EURODRIVE Base 150 is available either pre-filled in gear units and gearmotors shipped by SEW‑EURODRIVE 150 or for order in can and barrel packaging units to be employed by the user for servicing and maintenance purposes by OilOnline.

Advantages of GearOil by SEW-EURODRIVE Base 150

| This series of products is tested according to: | Specifications |

|---|---|

| SEW-Test-Specification-No. 070040313 | DIN 51517-3: CLP |

| ISO 6743-6 and ISO 12925-1: CKC / CKD | AGMA 9005/E02: EP |

Technical data of GearOil by SEW-EURODRIVE Base 150

| Technical Information | Unit | GearOil Base 150 |

|---|---|---|

| Identification (DIN 51502) | - | CLP 150 |

| Identification (ISO 12925-1) | - | CKC 150 |

| DIN ISO viscosity class (DIN ISO 3448) | - | 150 |

| Density, at 15 °C (DIN 51757) | kgm⁻³ | 892 |

| Kinematic viscosity (DIN ISO 3104) | - | - |

| 40 °C | mm²/s | 150 |

| 100 °C | mm²/s | 15 |

| Viscosity index VI (DIN ISO 2909) | - | 100 |

| Color number (DIN ISO 2049) | - | 3 |

| Flashpoint – Cleveland, open cup (DIN EN ISO 2592) | °C/°F | 250/482 |

| Pour point (DIN ISO 3016) | °C/°F | -24/-11 |

| Foam test (ISO 6247) | - | - |

| Sequence I/24 °C | ml | 0 |

| Sequence II/93.5 °C | ml | 0 |

| Sequence III/24 °C | ml | 0 |

| FZG scuff test | - | - |

| DIN ISO 14635-1, A/8,3/90 | Scuffing load | > 14 |

| DIN ISO 14635-1, A/16,6/90 | Capacity | > 14 |

| FAG FE8 rolling bearing test – rolling element wear (DIN 51819-3, D 7.5/80-80) | mg | < 5 |

| Micro pitting test (FVA 54 I-IV) | Scuffing load | 10 high |

| Four-ball EP test – fretting load (DIN 51350-2) | N | > 2200 |

| Corrosion on copper (DIN EN ISO 2160, 3h/100 °C) | Degree of corrosion | 1a |

| Corrosion protection – steel, method A: distilled water (DIN ISO 7120) | Degree of corrosion | 0 |

| Corrosion protection – steel, method B: salt water (DIN ISO 7120) | Degree of corrosion | 0 |

| Neutralization value (ISO 6618) | mg KOH/g | 0.35 |

| Minimum shelf life from manufacture – when stored in dry, frost-free rooms and in original sealed containers | Months | 72 |

Discover the benefits of OilOnline!

Are you looking to buy oil from OilOnline? Then you can take advantage of many benefits:

Our knowledge

is your strength!

At OilOnline, we have a team of passionate lubricant specialists with extensive knowledge and experience.

Detailed

advice

Our experts will assist you in choosing the best products, so you can get the most out of your vehicle or machine.

Uncompromising

Quality

At OilOnline, we only offer lubricants from globally renowned quality brands.

Save on

Lubricants

By ordering larger quantities, you can take advantage of price benefits at OilOnline.